Alexander Richter17 May 2021

Alexander Richter17 May 2021Could utilizing CO2 for geothermal energy production provide an option for geothermal power production? Scientists and technology players believe so.

In an article written for Energycue in Italy, Luigi Sambuceti, currently graduating from the Polytechnic of Turin in the master’s degree course in Energy and Nuclear Engineering, shares an interesting take on how CO2 can be used to utilise geothermal energy.

He describes the so-called CO2 Plume Geothermal technology (CPG), which allows to store CO2 to produce energy from geothermal

The US company TerraCOH has developed CPG technology capable of combining CO2 storage with geothermal energy. In this way it is possible to produce clean energy by exploiting the reduction of emissions.

Annual greenhouse gas emissions continue to rise, despite the Paris Agreements signed in 2015. Each year, more than 40 billion tons of carbon dioxide enter the atmosphere, slowing efforts against climate change, so a solution that can utilize these emissions to actually produce energy is rather interesting.

Two urgent challenges are to reduce emissions and at the same time integrate renewable energies. CO2 storage and geothermal energy production can combine these goals. In reality, using CO2 in geothermal plants is an innovative idea. Already in 2000 some geothermal systems exploited pressurized CO2, partly gaseous and partly liquid. The benefits were shallower wells and less heat losses .

CPG technology is different because it exploits not so much CO2 as a motive fluid, but the geothermal potential of its capture and storage.

The CCS ( Carbon Capture and Storage ) is the process of capturing carbon dioxide and subsequent storage . It serves above all to avoid greenhouse gas emissions from sectors where these emissions are difficult to eliminate.

For the capture there are different technologies divided into three groups: post-combustion, pre-combustion and oxy-combustion.

Post-combustion is the most used. It consists of mixing the exhaust fumes with a solution that captures the CO2 and precipitates to the ground. The solution is mainly composed of amines, alkaline oxides or ionic liquids. Membranes and cryogenic separation offer an alternative to the treatment of fumes.

Pre-combustion, on the other hand, occurs upstream of combustion. It uses the gasification process to transform the fuel into a mixture of carbon dioxide and hydrogen. The first is stored, the second is used in the combustion chamber. In this way, a primary fuel in liquid or solid phase can be converted into syngas.

With oxy-combustion, pure oxygen is used as an oxidizer. The oxygen for combustion is obtained from the air with a required purity above 95%. The advantage is to have a CO 2 concentration higher than 80%. On the other hand, the cost of the plant is clearly higher, having to add the section for the production of pure oxygen.

But how does CPG technology work?

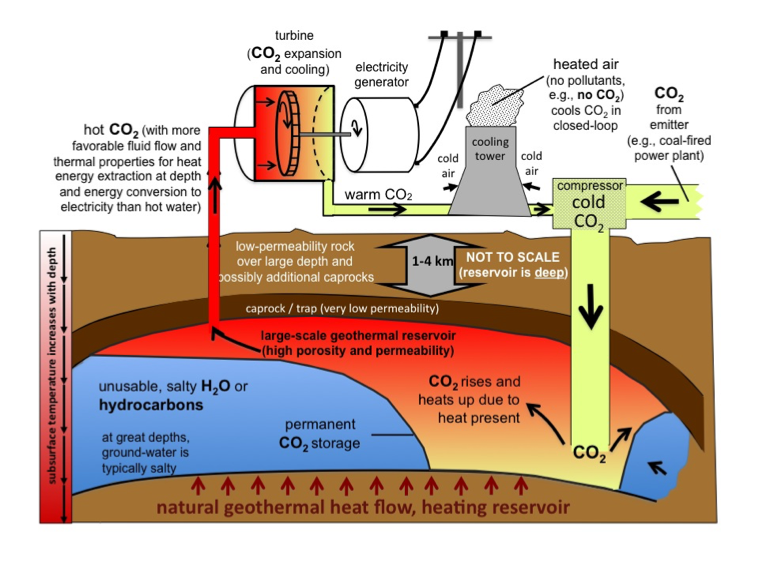

CO2 plume geothermal CPG technology mainly uses carbon dioxide captured by thermal power plants. The CO2 is injected into saline aquifers that take it 1-1.5 km underground where it heats up thanks to geothermal heat. The extracted ‘hot’ CO2 sets a turbine in motion to produce electricity.

Picture above shows a model of a CO2 Plume Geothermal System (CPG) from the Numerical Modeling project of CPG systems ETH in Zurich, Switzerland.

But why exactly carbon dioxide? Because compared to traditional fluids (such as water with a high salt concentration), it has many advantages:

- density varies more with temperature, so less energy is consumed with pumping

- thanks to a thermo-siphoning effect, the anhydride circulates more easily

- it has a low reactivity, therefore it reduces the fouling of wells and ducts

- it is not very viscous, so high pressure losses are avoided

Let’s make a comparison. A 1.5 km deep CO2 system produces more power than a 4km water system. Beyond 5 km, systems with CPG technology produced between 0.7 MWe and 9 MWe more.

The potential of this new technology is recognized, but for its effective implementation, adequate energy policies will be needed in a short time .

Source: EnergyCue